Application – FFS, Box making, thermoforming, Vacuum forming, Blister forming, tubes etc.

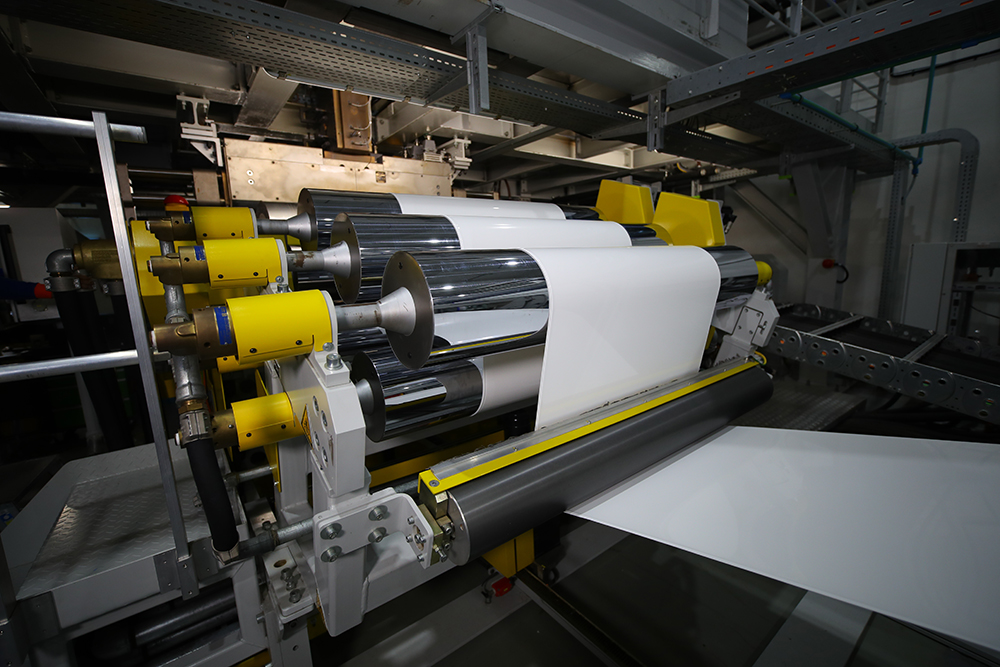

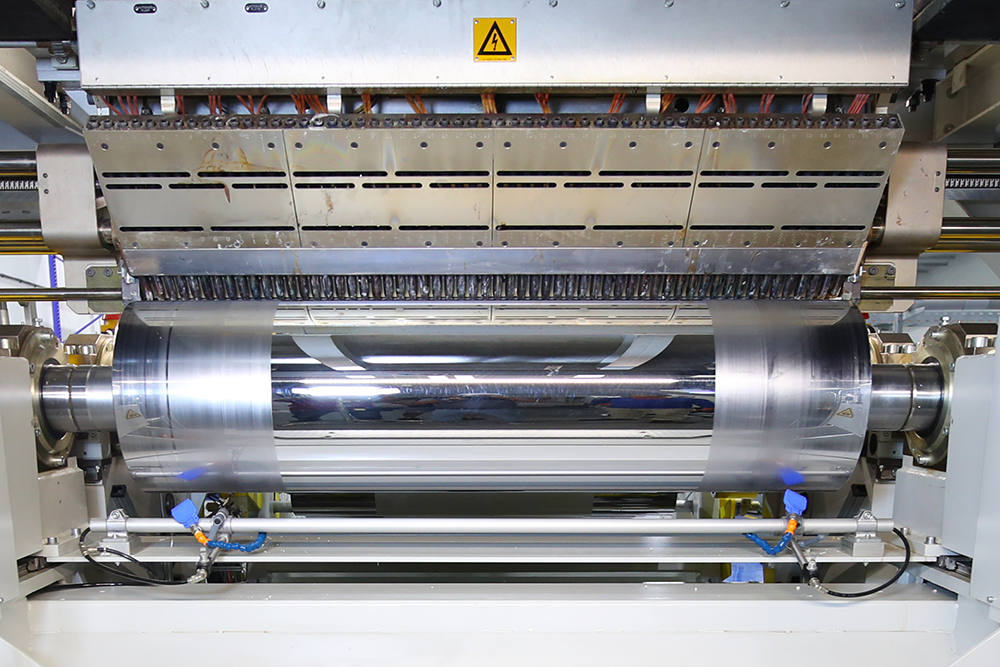

EXTRUSION

- State of art European extrusion machines.

- Capacity to extrude up to 11 layers.

– Capacity to extrude various polymers like PP, PP-EVOH, PS-EVOH, PET ( rPET, GPET, APET), HIPS & GPPS ETC. - Camera for online defect detection.

- Auto thickness gauge monitoring for precise thickness.

- Surface treatment for Lamination/ printing application.

- Option to provide in various colours/bi-colours sheets (Subject to MOQ).

- Thickness ranges from 200 mic. to 2000 mic.

- Maximum width 1200 mm.

- Capability to offer sheets with PCR material.

THERMOFORMING MACHINES

- With a range of indigenous as well as European thermoforming machines.

- Ability to process PP, PP-EVOH, PET, PS & PLA.

- Preheater for uniform distribution of material.

- Accurate mould temperature control.

- Auto stacking of parts ensures no human intervention.

- Inline skeleton grinder.

- Equipped with a range of moulds with 150+ products in various shapes and sizes.

- Consistent in producing superior quality products.

DECORATION – DRY OFFSET PRINTING

DECORATION (Offering eye-catching decorative options, Attention drawing graphic packaging styles)

DECORATION – SLEEVING

- Sleeving meets aesthetic demands

- Auto-loading of cup

- Auto sleeve applicability.

- Auto stacking and counting of cups